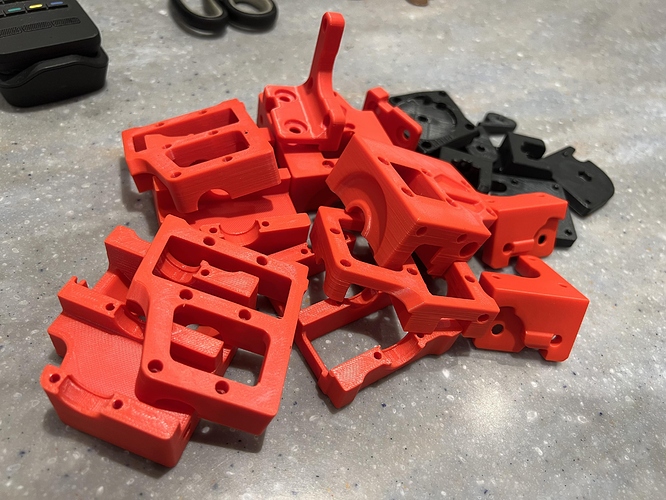

Some of you might have noticed me camped out in front of the Bambu quite a bit lately. It’s because I’m building a 3D printer that itself is composed of quite a few 3d printed parts, which the Bambu produces quite nicely:

These are printed in Bambu’s own ASA filament. I’m not super thrilled with the colour choices they have available but functionally the parts appear top notch.

The design itself is a VORON 2.4 which is the result of an open source effort you can read more about here. It’s a pretty uncompromising fit out which should be competitive with the Bambu X1’s performance… at nearly twice the price (sigh). One benefit will be the larger build area, which will be 350mm x 350mm x 350mm when all is said and done.

Progress is going a little slow, not just because it requires probably over a 100 individually printed parts, but because my 6 year old son and I are building it together and he insists I make no progress without him, so it’s been a great bonding activity in the evening.