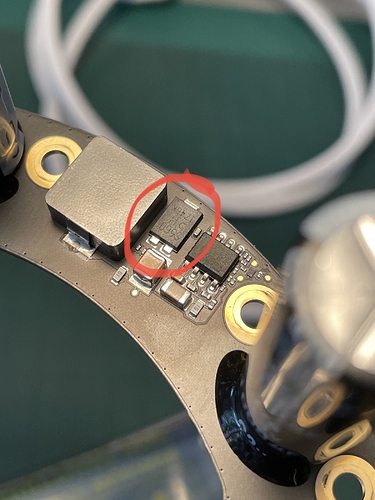

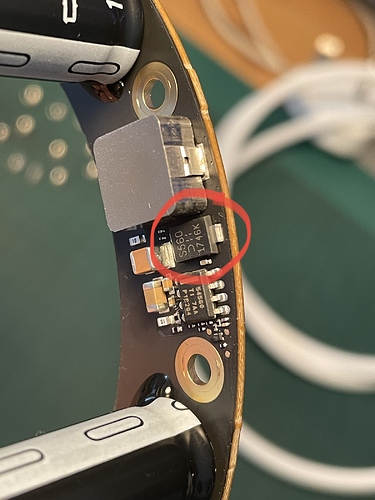

Does the space have a solder rework station (hot air) and can anyone hold my hand through replacing a tiny surface mounted diode (pics attached)? Trying to resurrect a bricked HomePod and have stumbled at this stage of the tutorial… tried removing it with a conventional soldering iron but no dice.

Hey @simoneves, I’m new to the space so maybe someone more experienced will be able to help more. But for what it’s worth, I was in the space yesterday to collect my fob and was having a look at what was available. I saw what I’m pretty sure is a hot air rework station, but didn’t use it, so can’t confirm it works.

If for some reason it doesn’t, I’m having mine shipped down from Scotland, but thats at least a week away. Would gladly help if I can.

You mentioned your soldering iron didn’t do the trick… it didn’t melt the solder?

David.

Yes space has generic 858d hot air gun in working order. I can show you or maybe someone else, but if noone is around it should be rather easy overall to desolder. Use thin nozzle, circular motion around pads, don’t set temperature more than 20 degrees than necessary to melt the solder - I’d start with 250-270°C to see how it goes, be patient air gun is slow - when the board heats up and solder begins to melt - pick it up with tweezers. Wipe the pads flat with solder wick and conventional iron before soldering a new one.

Careful with those 0402 chips on the side - reduce air flow for not to blow them away if you see solder around them is melting!

Thanks David! I tried using my soldering iron but I couldn’t seem to melt the solder enough to get the component to budge. Also terrified of just frying everything… Maybe I need all three pads to heat at the same time to dislodge?

Thanks Roman! This is a really useful guide.

We have an infrared hoven too, you could use it to bring the board to temperture

couldn’t seem to melt the solder

To make life easier you can try adding some extra solder to pads, if it’s regular 60/40 it will have lower melting temperature in comparison to industrial lead-free one. Solder on the tip of iron increases contact area of your iron, instead of touching the pad in single point you do it with whole molten drop. Extra solder on pad increases thermal mass, you’ll have a tiny bit more time until it gets back solid.

Any blobs that appear, remove with solder wick and lots of flux.

Even better than 60/40, you can also get bismuth-based low temperature solder (ChipQuik and similar) that can be used to alloy with the existing solder and lower its melting point to 100C or less.

That’s a mess to clean up.

We have a good session reparing a motherboard yesterday with hot air.

Pre-heating the board makes a huge difference. I’ve got my own hot air rework station that has an IR heater that warms the board up from the underside. The time to melt the top side of a pre-heated board is like night and day. It also reduces the exposure of the chips to the high temp for soldering/removal. Just keep the pre-heat temp low enough. I don’t recall the recommended temp because it’s been awhile, but there are like tutorials out there with suggested temps.