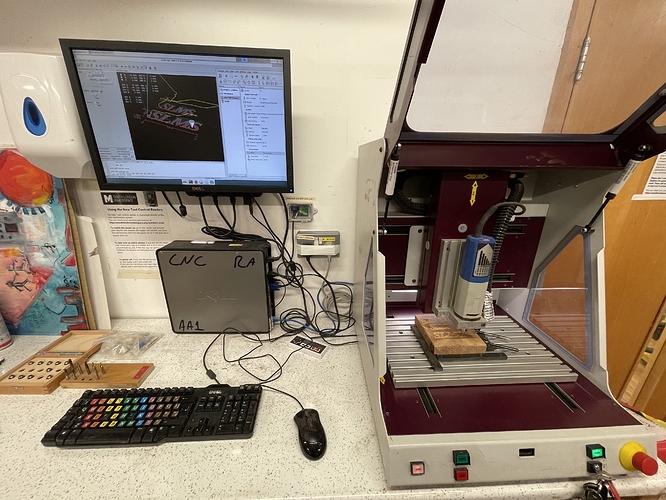

Cleaned up the CNC area and fired up the machine! A few little bits to clean up, but looking good!

Nice work!

Wow! Great! I am looking forward to seeing it in action!

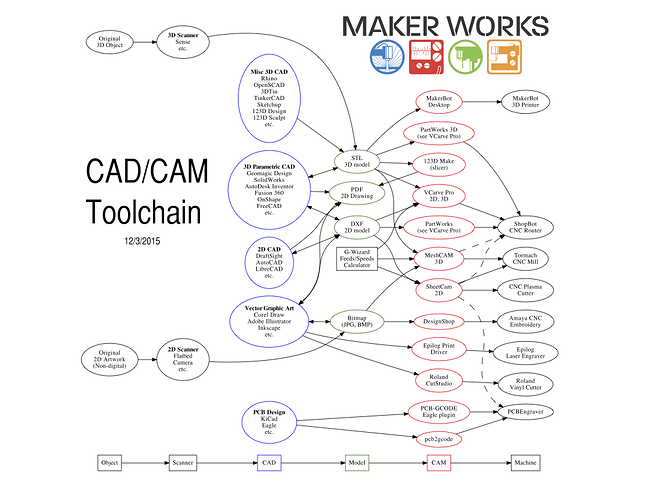

@asander1 what CAD/CAM software should I be looking at? Trying to get away from Fusion 360 is possible!

Great question!

Technically anything that will generate g-code…

I have been using Fusion 360 but yea - my educational license (I work for a University part of the time) has expired and I am applying to renew. So I understand many may struggle to get a long term license… is that where you are stuck with Fusion?

The long answer is it depends on what you are doing… for example here is another Makerspaces’ tool chain:

https://www.maker-works.com/cadcam-toolchain

Looks like they pay for a bunch of these tools and have them available on workstations in the space.

For us I think we should evaluate some of these and see if any are worth paying for… specifically ones that have maker friendly licenses… eg.

VCarve Pro Makerspace edition- $99 a year

https://www.vectric.com/support/makerspace-sign-up

Solidworks Maker license- $99 a year (avail. 2H 2021)

https://www.solidworks.com/solution/company-type/makers

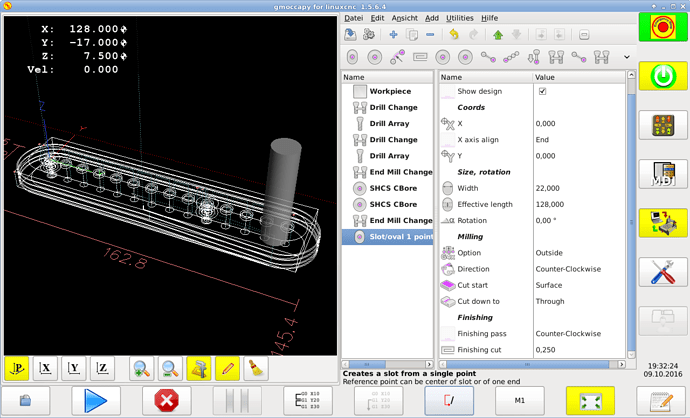

A side note- we also have NativeCAM installed to allow simple jobs without the 3D modelling… I think for inductions on the machine this will be a good place to start - here is a description of that…

“NativeCAM gives you a basic toolkit that you can use to quickly create various shapes without having to write G-Code - a lot of the time it’s all you need to create (for example) a row of holes in a piece, or mill a pocket or slot in something. You don’t need to design it in CAD, just set some basic parameters in NativeCAM and generate the G-code.

You can do a surprising amount, but the basics are:

-

Straight, square, or round slots or pockets including D-shaped (circle with bit cut off)

-

Hole drilling including rows of holes, circles of holes (PCD)

-

Straight or curved lines, linked together to create polygons (polyline)

-

Engrave text

There’s a fair bit more but for basic work it’s very useful.”

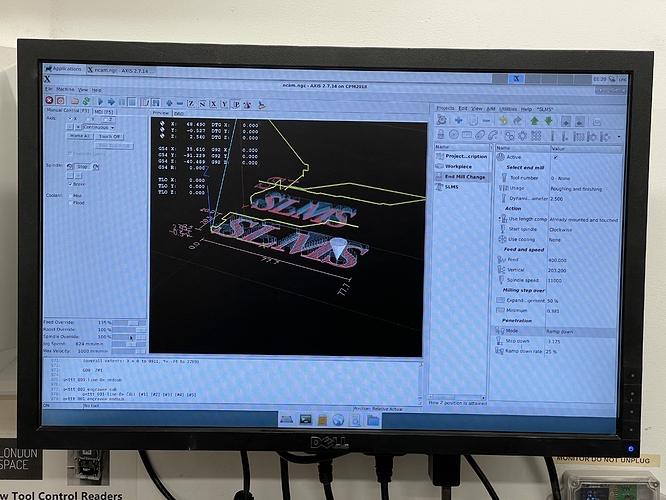

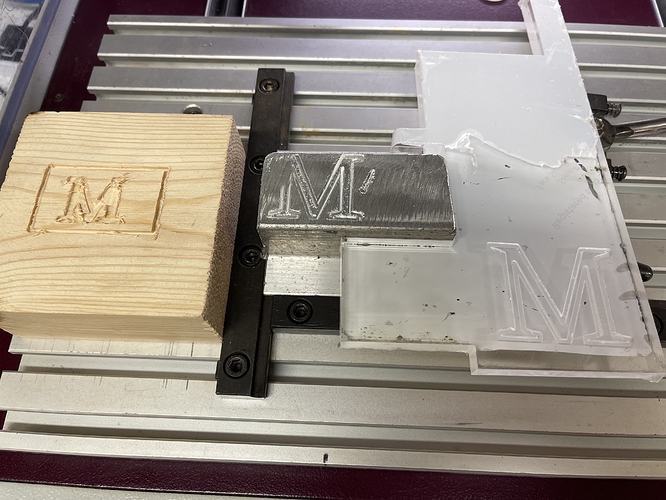

Testing the CNC / new Henry with some different materials… working well!, still want to hook Henry up properly and add an air line/mister for cooling when doing soft metals…

This test piece wasn’t flat, hence the missing engraving in the top left corner…

Wood, aluminium and plastic…

While I remember, someone at works is after a component prototyped on a mill with a fairly rapid turnaround / low lead time. Will be produced in small batches (maybe 60 or 90) out of steel.

Any suggestions would be appreciated

i have been using aries[isis pcb programe it can output a drill plot

with the right size bit should be able to make some proto bord

only the holes to handwire

Nice, I will check that program out!

did you find the program the two parts are within PROTES

www.labcentre.co.uk

that machine is runing on linux cnc yes

how about an online induction